Industries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

- Civil Engineering

- CPG

- Building Automation

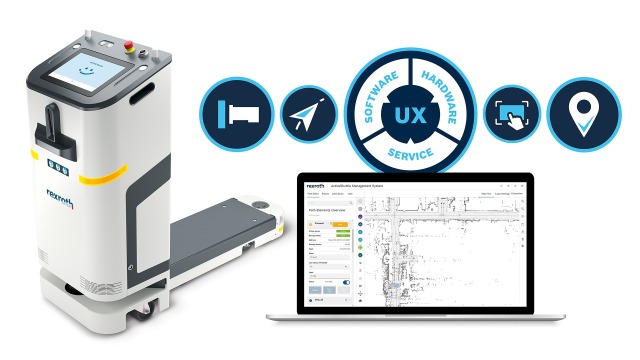

- Warehouse Automation

- Aerospace

Service

OverviewBuy

OverviewBlog

OverviewProduct groups

OvervieweConfigurators and Tools

Overview

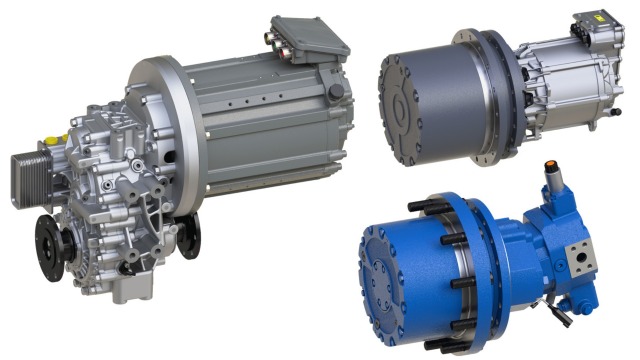

YOUR PARTNER FOR THE NEXT GENERATION OF MOBILE MACHINES

Whether driving or working, hydraulic, hybrid or fully electric, Bosch Rexroth offers highly efficient, low noise and powerful electric motors, generators, inverters and hydraulics combined with modular software modules.